FIBER-REINFORCED POLYMERS FOR INFRASTRUCTURE REPAIR

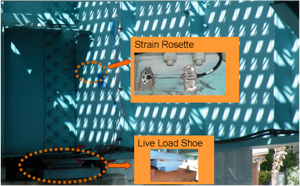

With excellent corrosion resistance, high strength-to-weight ratio, and stiffness-to-weight ratio, externally bonded FRP composites provided a time and strength efficient means to strengthen reinforced concrete (RC) structures and other materials used commonly in civil infrastructure. Ongoing research at UCF aims to investigate the ability of externally-bonded composite systems to resist service environments similar to that of the State of Florida when used in bridge applications.

- Combined effects of environmental loads and fatigue loads are investigated through accelerated laboratory testing.

- Small-scale specimen and large-scale RC beam testing to ultimate load to investigate bond slip and fiber-adhesive-substrate interaction.

- Multiple fibers and resin combinations including polyurethane-carbon and epoxy-basalt.

- Applications to other infrastructure systems

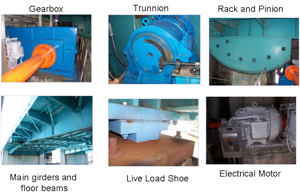

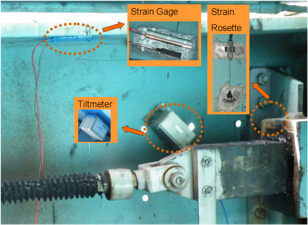

STRUCTURAL HEALTH MONITORING OF MOVEABLE BRIDGES

Issues related to movable bridges:

- Design of a SHM framework for a movable bridge to deal with those issues

- Technical and non-technical challenges of the SHM system implementation

- Prediction of the bridge performance

ULTRA-HIGH PERFORMANCE CONCRETE FOR INFRASTRUCTURE

Ultra-high performance concrete (UHPC) has a similar constitution to normal concrete, but with the low water-cement ratio. Some UHPCs do not contain large aggregates, but all include fibers made of steel or plastic. Compressive strengths can be as high as 200 MPa (28 ksi) after heat treatment and as high as 1.8 ksi in tension. The dense structure of UHPC prevents the invasion of air and water, allowing a service life of over 100 years even under severe conditions. In addition, UHPC exhibits high ductility due to the bridging effect of the fibers and shows strain hardening effects under uniaxial tension or flexural testing. Research Area at UCF on UHPC includes:

- Material characterization of UHPC, static, dynamic and fatigue

- Application of UHPC in movable bridges, design the lightweight high strength decks to replace steel grid decks

- Application of UHPC in the superstructure of bridges in the seismic region

- Precast bridge modulus made of UHPC

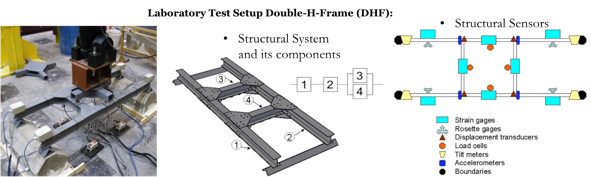

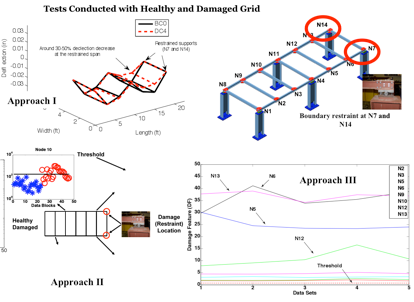

PHENOMENOLOGICAL STEEL GRID MODEL

Different parametric and non-parametric methods are used for damage detection

- Approach I: Modal parameter based

- Approach II: Time series analysis with outlier detection

- Approach III: A novel time series analysis with sensor clustering

One method may perform very well for one structure and/or damage case but may not perform well another case and therefore a combination of different methods should be used for damage detection.

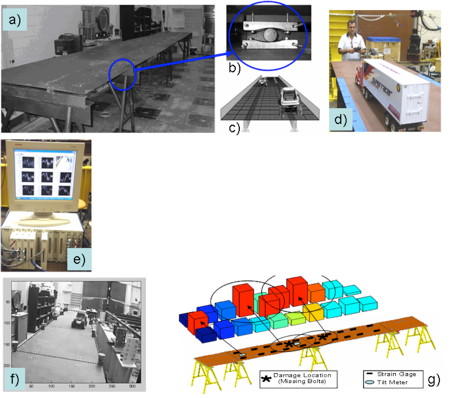

UCF 4-SPAN BRIDGE MODEL

The bridge model is an experimental setup to study sensor fusion and video monitoring (a). Supports can easily be changed to roller, pin, or fixed boundary conditions (b). Girder and deck can be connected together by using bolts at different locations to modify the stiffness of the system and to simulate damage. Radio-controlled vehicles can crawl over the deck with different loading conditions (c&d). While a video camera is used to identify and track the vehicle, a data acquisition system (e) collects the data from a set of strategically located sensors to be correlated with the video stream (f) in real time to detect damage (g). The bridge is not a scaled-down model; however, its responses are representative of typical values of most small to medium span bridges.

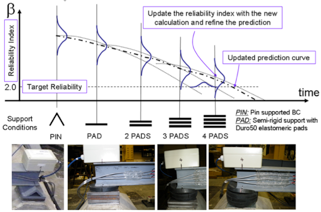

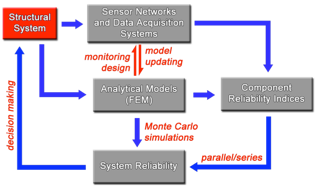

SYSTEM RELIABILITY-BASED STRUCTURAL HEALTH MONITORING

Probabilistic Evaluation of Structural Condition

Incorporation of Epistemic and Aleatory Uncertainties

Prediction of Future Performance for Optimum Management and Operation